Products

View More

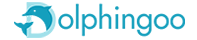

We specialize in the production of needle roller bearings and have produced more than 300 varieties, including stamped outer ring full needle roller bearings, stamped outer ring with cage needle roller bearings and cage needle roller assemblies, plane thrust needle roller bearings, elastic needle roller bearings, clutch bearings, one-way needle roller bearings, solid ring needle roller bearings, etc.

-

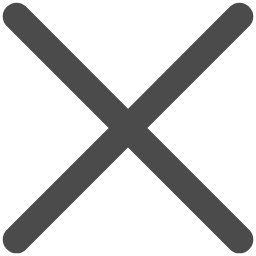

Automotive Sector

Bearings are widely used in automobiles and play an important role. They are used in everything from engines and chassis to electrical assemblies. Automotive bearings are categorized into two main types: plain bearings and rolling bearings.

Learn More -

Electric Tool Field

All power tools contain high-speed motors, so power tool bearings are indispensable transmission components on power tools. The quality of power tool bearings determines the quality of power tools.

Learn More -

Agricultural Sector

Bearings are widely used in automobiles and play an important role. They are used in everything from engines and chassis to electrical assemblies. Automotive bearings are categorized into two main types: plain bearings and rolling bearings.

Learn More -

Textile Industry

Bearings are widely used in automobiles and play an important role. They are used in everything from engines and chassis to electrical assemblies. Automotive bearings are categorized into two main types: plain bearings and rolling bearings.

Learn More -

Mining Industry

Bearings are widely used in automobiles and play an important role. They are used in everything from engines and chassis to electrical assemblies. Automotive bearings are categorized into two main types: plain bearings and rolling bearings.

Learn More -

Shipbuilding Industry

Bearings are widely used in automobiles and play an important role. They are used in everything from engines and chassis to electrical assemblies. Automotive bearings are categorized into two main types: plain bearings and rolling bearings.

Learn More

About Us

Suzhou Dongwu Needle Bearing Co., Ltd. is located in Suzhou Industrial Park, a national level economic and technological development zone. It is a national high-tech enterprise specializing in the production of needle roller bearings.

With Shanghai in the east, Taihu Lake in the west, Zhejiangprovince in the south, the Changjiang River inthenorth, TheSIP has developed a sea-land-air-rail three-dimensional network. Adjoining with Science and EducationInnovationZone,the SIP provides strong flavor of humanbeingsandattracts lots of excellent enterprises. All of aboveprovideanexcellent supporting platform for the company's technological and production development.

View More-

1993Year

Establishment

-

700+

Bearing types

-

20+

Application industry

-

100+

Serving the world (countries or regions)

Why Choose Us

We have established an efficient and flexible operating system that can quickly respond to market changes and meet customer needs.

-

Production Scale

Our factory covers an area of 90,000 square meters and has advanced aluminum alloy CNC equipment and shell injection molding production lines. This scale enables us to meet high demand while maintaining production efficiency.

-

Monthly Capacity

With a strong production capacity of 1 million units per month, we ensure continuous supply, scalability and fast delivery to meet a variety of order needs from small batches to large quantities.

-

Wide Product Range

We specialize in laser products, including laser training cartridges, calibration tools, blank ammunition and advanced laser sights, with wavelength options including 850nm (infrared), 650nm (red), 520nm (green), 450nm (blue) and 405nm (violet) for a variety of applications.

-

R&D and Product Development

With more than 12 years of OEM experience, our strong R&D and manufacturing capabilities enable us to provide tailor-made high-quality solutions. Our products undergo rigorous waterproof, shockproof and fogproof testing to ensure reliability and durability under all conditions.

News

-

Feb 27, 2025

Feb 27, 2025What is a bearing retainer? What materials are bearing retainers made of?

The bearing retainer, also known as the cage, is a key component of a bearing. Its function is to enclose and isolate the rolling elements, allowing them to follow their movement and often guiding them. The cage must withstand stresses caused by friction, strain, and inertia, as well as chemical corrosion from lubricants, lubricant additives, substances generated by lubricant aging, organic solvents, and coolants. Therefore, the cage's design and material are crucial to its performance and bearing reliability.

View More -

Feb 27, 2025

Feb 27, 2025What is a bearing retainer? What materials are bearing retainers made of?

The bearing retainer, also known as the cage, is a key component of a bearing. Its function is to enclose and isolate the rolling elements, allowing them to follow their movement and often guiding them. The cage must withstand stresses caused by friction, strain, and inertia, as well as chemical corrosion from lubricants, lubricant additives, substances generated by lubricant aging, organic solvents, and coolants. Therefore, the cage's design and material are crucial to its performance and bearing reliability.

View More -

Feb 27, 2025

Feb 27, 2025What is a bearing retainer? What materials are bearing retainers made of?

The bearing retainer, also known as the cage, is a key component of a bearing. Its function is to enclose and isolate the rolling elements, allowing them to follow their movement and often guiding them. The cage must withstand stresses caused by friction, strain, and inertia, as well as chemical corrosion from lubricants, lubricant additives, substances generated by lubricant aging, organic solvents, and coolants. Therefore, the cage's design and material are crucial to its performance and bearing reliability.

View More

We'd love to hear from you.

Please leave a message, we will get in touch with you as soon as possible!